Unlocking Business Growth with Premier Metal Fabricators and China Rapid Prototype Suppliers

In today's competitive manufacturing landscape, understanding the role of advanced metal fabricators and partnering with the right china rapid prototype suppliers can significantly impact your company's ability to innovate, reduce costs, and accelerate time-to-market. As industries evolve rapidly, embracing state-of-the-art technologies and strategic supplier collaborations become paramount for sustained business success.

Understanding the Vital Role of Metal Fabricators in Modern Manufacturing

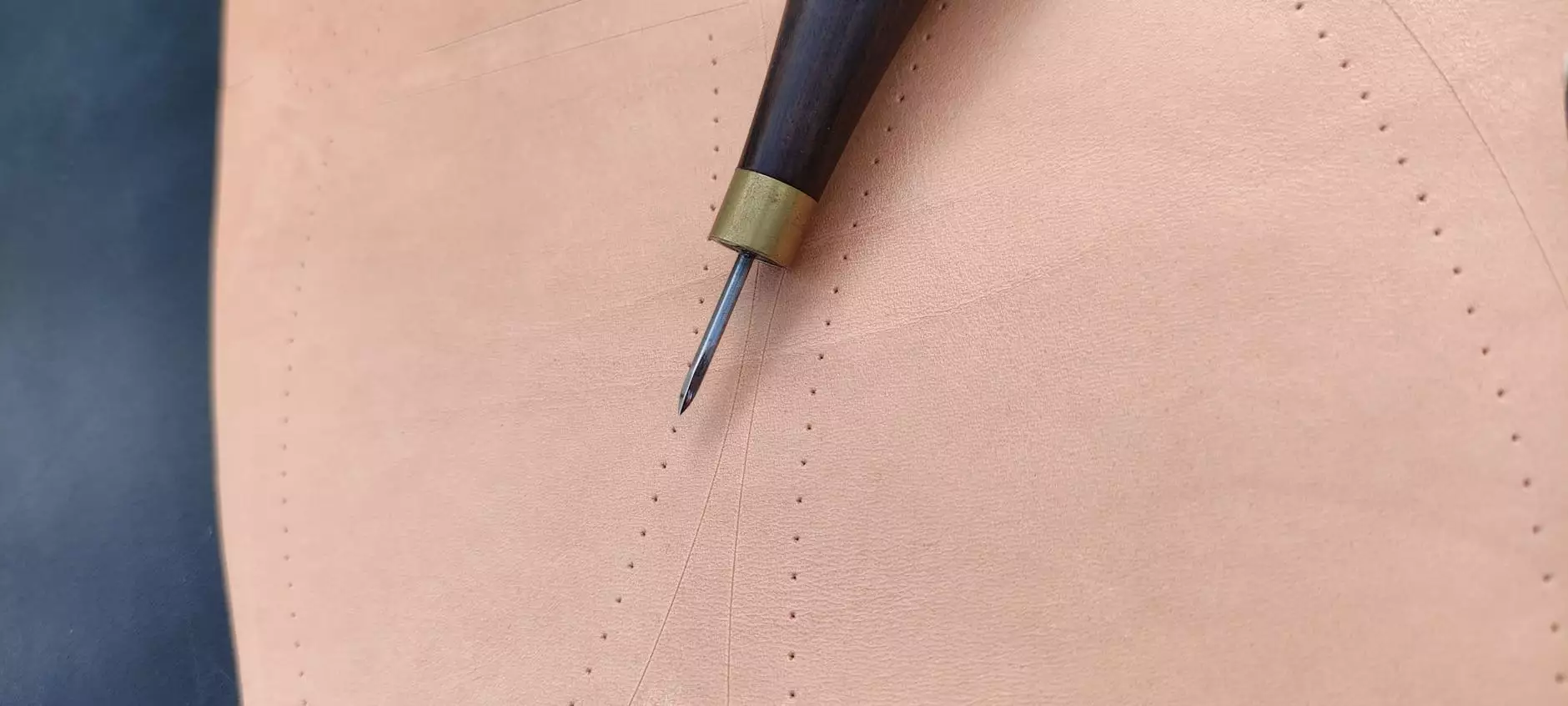

Metal fabricators are the backbone of various industries, including aerospace, automotive, construction, and consumer electronics. Their expertise involves transforming raw metal materials into complex, durable components through processes like cutting, welding, bending, and assembly. The quality and precision of their work directly influence the performance, safety, and longevity of end products.

Why Metal Fabricators Are Essential for Your Business

- Precision and Customization: Modern metal fabricators utilize advanced machinery to produce highly precise components tailored to specific business needs.

- Material Versatility: They work with a wide range of metals such as steel, aluminum, titanium, and specialty alloys, enabling versatility across different industries.

- Cost-Efficiency: Effective fabrication processes can reduce waste and optimize material use, lowering overall production costs.

- Accelerated Lead Times: Well-equipped fabricators streamline production workflows, enabling faster delivery schedules.

- Quality Assurance: Adherence to international standards like ISO and ASME ensures reliable, high-quality end products.

Leveraging China Rapid Prototype Suppliers for Competitive Advantage

The term "china rapid prototype suppliers" signifies companies in China specialized in quick, cost-effective prototype development vital for product testing, design validation, and iteration. Partnering with the right supplier in this domain can dramatically reduce your product development cycle and enable faster market entry.

Advantages of Engaging with China Rapid Prototype Suppliers

- Lower Manufacturing Costs: Due to economies of scale and operational efficiencies, Chinese suppliers often deliver prototypes at a fraction of Western costs.

- Rapid Turnaround Times: Many suppliers boast turnaround times ranging from 24 hours to a few days, facilitating quick iterations.

- Access to Advanced Technologies: Leading Chinese prototype suppliers employ CNC machining, 3D printing, injection molding, and other cutting-edge techniques.

- High-Quality Standards: Reputable suppliers adhere to international quality controls, ensuring prototypes meet rigorous specifications.

- Flexible Production Runs: Small batch production is often available, ideal for testing and initial market launches.

Integrating Metal Fabrication with Rapid Prototyping for Seamless Product Development

Successful product development hinges on the seamless integration of metal fabrication and rapid prototyping. Modern manufacturers are increasingly adopting a synchronized approach where prototypes are fabricated with real production materials, providing accurate testing scenarios and smoother transition from prototype to mass production.

Benefits of Combining Metal Fabrication with Rapid Prototyping

- Enhanced Design Validation: True-to-material prototypes help identify potential issues early, reducing costly revisions.

- Accelerated Development Cycles: Reducing iterations speeds up bringing products to market.

- Improved Manufacturing Readiness: Early integration ensures manufacturing processes are optimized for scale-up.

- Cost Savings: Early detection of flaws prevents expensive rework during mass production.

Choosing the Best Metal Fabricator: Key Considerations

When selecting a metal fabrication partner, especially one capable of supporting rapid prototyping needs, the following factors are crucial:

- Technical Capabilities: Verify machinery, processes, and materials available.

- Quality Certifications: Look for ISO 9001, ASME, or equivalent standards.

- Experience and Industry Reputation: Assess past projects, client testimonials, and industry recognition.

- Geographic Proximity and Supply Chain Logistics: Consider logistics for faster delivery and communication.

- Cost Efficiency and Flexibility: Balance quality with budget constraints and project flexibility.

Top Strategies for Collaborating with China Rapid Prototype Suppliers

Successful collaboration requires clear communication, rigorous quality control, and understanding of cultural differences. Here are key strategies:

- Detailed Specifications: Provide comprehensive CAD files, material requirements, and tolerances.

- Early Engagement: Initiate contact early to design prototypes aligned with manufacturing capabilities.

- Regular Quality Checks: Establish checkpoints and inspection protocols to maintain standards.

- Strategic Partnership Approach: Cultivate long-term relationships that foster trust and continuous improvement.

- Leveraging Technology Tools: Use communication platforms, project management software, and collaboration tools for seamless coordination.

Case Studies: Success Stories in Metal Fabrication and Rapid Prototyping

Innovative Aerospace Components

A leading aerospace manufacturer collaborated with a China rapid prototype supplier to develop complex aerospace brackets. Through advanced CNC machining and rigorous quality standards, the project achieved a 40% reduction in prototype development time, enabling faster certification and market entry.

Consumer Electronics Breakthroughs

A startup used rapid prototyping services from China to iterate on metal enclosures for wearable devices. The partnership allowed multiple design changes, cutting costs substantially and reducing time-to-market by over 50% compared to traditional methods.

The Future of Metal Fabrication and Rapid Prototyping in Business

Emerging technologies like artificial intelligence, machine learning, and automated manufacturing are revolutionizing both metal fabrication and rapid prototyping processes. Businesses that leverage these innovations can expect to see:

- Greater precision and consistency

- Faster iteration cycles

- Enhanced customization options

- Reduced environmental impact

- Increased scalability

Companies like deepmould.net are at the forefront of delivering integrated solutions combining high-end metal fabrication and rapid prototyping. Their expertise ensures your product development process is not only efficient but also aligned with the latest industry standards.

Conclusion: Position Your Business for Growth with Strategic Partnerships

In conclusion, growing your business today requires strategic engagement with experienced metal fabricators and china rapid prototype suppliers. These partnerships provide a competitive edge by enabling innovation, reducing costs, and shortening time-to-market. Embrace cutting-edge technologies and cultivate strong supplier relationships to unlock new opportunities and secure your position as a leader in your industry.

By investing in quality, leveraging international expertise, and staying ahead of manufacturing trends, your company can achieve remarkable growth and resilience in a rapidly evolving market.