The Importance of Grain Moisture Management in Agriculture

Grain moisture is a crucial factor in the agricultural industry, significantly affecting the quality and shelf life of harvested grains. Understanding how to manage moisture levels effectively can mean the difference between profit and loss for farmers and stakeholders in the agricultural sector. This article delves into the significance of grain moisture management, the technology available to measure and regulate it, and how businesses like TSGC Inc. are setting the standard in farm equipment repair and farming equipment.

Understanding Grain Moisture

Simply put, grain moisture refers to the amount of water content present in grains right after harvesting. The moisture level is crucial because it influences the grain's weight, storage stability, and overall quality. A grain's moisture content is usually measured as a percentage of the total weight, with ideal ranges varying for different types of grain.

Why Grain Moisture Matters

Managing grain moisture is essential for several reasons:

- Quality Control: Proper moisture levels ensure that grain retains its quality during storage, reducing the risk of spoilage.

- Market Value: Grains with inappropriate moisture levels often fetch lower market prices, affecting the farmer's profitability.

- Storage Longevity: Excess moisture can lead to mold growth, insect infestations, and other quality deterioration, compromising long-term storage viability.

- Efficiency in Harvesting: Understanding moisture levels can guide harvest timing, ensuring grains are collected at their peak quality.

Measuring Grain Moisture

Today’s technology offers farmers advanced tools for accurately measuring grain moisture. Moisture meters and sensors are vital in helping farmers assess moisture content in real time. Here are some commonly used methods and equipment:

1. Portable Moisture Meters

These devices allow farmers to take immediate measurements in the field. They are user-friendly and provide quick readings, which can aid in making immediate harvesting decisions.

2. Inline Moisture Sensors

Installed in grain handling systems, inline moisture sensors continuously monitor moisture levels as grains are processed. This technology ensures optimal moisture control during storage and transportation.

3. Laboratory Testing

For the most precise measurements, samples can be sent to labs, where they undergo comprehensive moisture analysis. This option is beneficial when quality control is paramount.

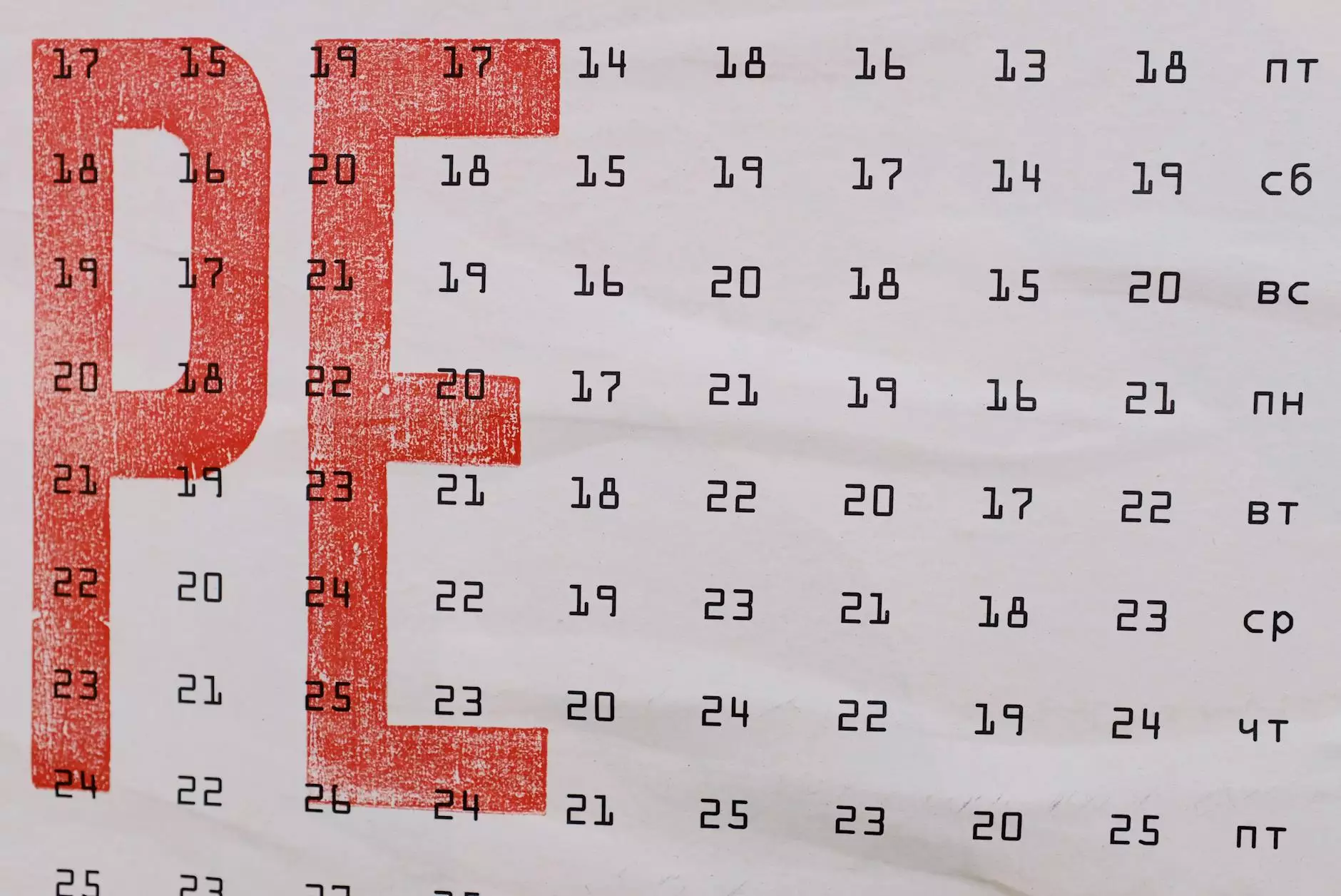

Optimal Moisture Levels for Different Grains

Different types of grains require specific moisture content to maintain quality during storage. Here’s a brief overview:

- Wheat: Ideal moisture content ranges from 12-14%.

- Corn: Should be dried to about 15% moisture for safe storage.

- Rice: Should maintain moisture levels around 14%.

- Barley: Ideally, moisture levels should be between 12-13%.

Impact of Grain Moisture on Farming Equipment

The management of grain moisture can significantly impact the functionality and longevity of farming equipment. Here’s how:

Storage Equipment

Grains with excessive moisture can lead to corrosion and malfunctioning of silos and storage bins. Proper moisture management protects the integrity of the equipment, ensuring that it lasts longer and operates efficiently.

Grain Handling Equipment

Moisture levels affect the wear and tear on combines and grain dryers. If grain is too wet, it makes machinery work harder, leading to increased maintenance and repair costs.

Drying Equipment

Grain dryers are essential tools for reducing moisture levels in harvested crops. Understanding the moisture content before the drying process is crucial for optimizing energy usage and achieving desired results quickly.

Best Practices for Managing Grain Moisture

Implementing robust moisture management practices will enhance grain quality and ensure excellent profitability. Here are some best practices:

1. Timely Harvesting

Harvest grains when they are at optimal moisture levels. This practice prevents spoilage during storage and ensures better market quality.

2. Proper Storage Conditions

Ensure that storage facilities are well-ventilated and the temperature is controlled to prevent condensation, which can increase moisture levels.

3. Regular Monitoring

Use moisture meters and sensors to frequently check moisture levels throughout storage and handling processes.

4. Efficient Drying Techniques

Utilize modern grain drying equipment, ensuring that drying is conducted under controlled environments to avoid damaging grains due to overheating.

Technology's Role in Grain Moisture Management

Modern farming equipment incorporates advanced technology to assist with moisture management:

- Automated Monitoring Systems: Some farming operations use systems that automatically monitor moisture and adjust conditions as necessary.

- Data Analytics: Employing data analytics helps farmers understand moisture trends and make informed decisions based on historical data.

- Remote Sensing: Drones equipped with sensors can provide real-time moisture content data for large fields.

The Role of TSGC Inc. in Grain Moisture Management

As a trusted leader in farm equipment repair and sales, TSGC Inc. offers various solutions tailored to meet the needs of farmers. Here’s how they contribute:

Expertise in Equipment Maintenance

TSGC Inc. provides necessary maintenance services to ensure that moisture management equipment operates effectively. Regular servicing minimizes downtime and extends equipment life.

Quality Farming Equipment

By supplying high-quality moisture meters and drying equipment, TSGC Inc. empowers farmers to manage their grains efficiently and effectively.

Educational Resources

TSGC Inc. offers training and resources to help farmers understand the significance of grain moisture and how to manage it properly through workshops and online content.

Conclusion

Understanding and managing grain moisture is vital for any agricultural operation aiming for success. By employing the right tools, best practices, and partnering with expert organizations like TSGC Inc., farmers can ensure high-quality yields and protect their investments. With the advancement of technology in agriculture, there has never been a better time to focus on moisture management. By prioritizing grain moisture control, farmers can enjoy increased market opportunities, lower degradation risks, and ultimately, robust profitability.

By embracing these practices and insights, agricultural stakeholders can ensure they remain competitive in today’s market while maintaining the quality and longevity of their grains and equipment.