Transforming the Construction Industry: The Role of a Concrete Mixing Plant Manufacturer

In the construction industry, the efficiency and quality of concrete are paramount. At the heart of this process lies the crucial role played by a concrete mixing plant manufacturer. This article delves into the significant contributions of such manufacturers, highlighting their technologies, sustainability efforts, and the future of concrete mixing.

The Importance of Quality Concrete in Construction

Concrete serves as the backbone of most construction projects, providing structure and integrity. High-quality concrete is essential not only for the longevity of structures but also for safety and performance. The mixing process directly impacts the final product's quality, making it vital for organizations to partner with reliable concrete mixing plant manufacturers.

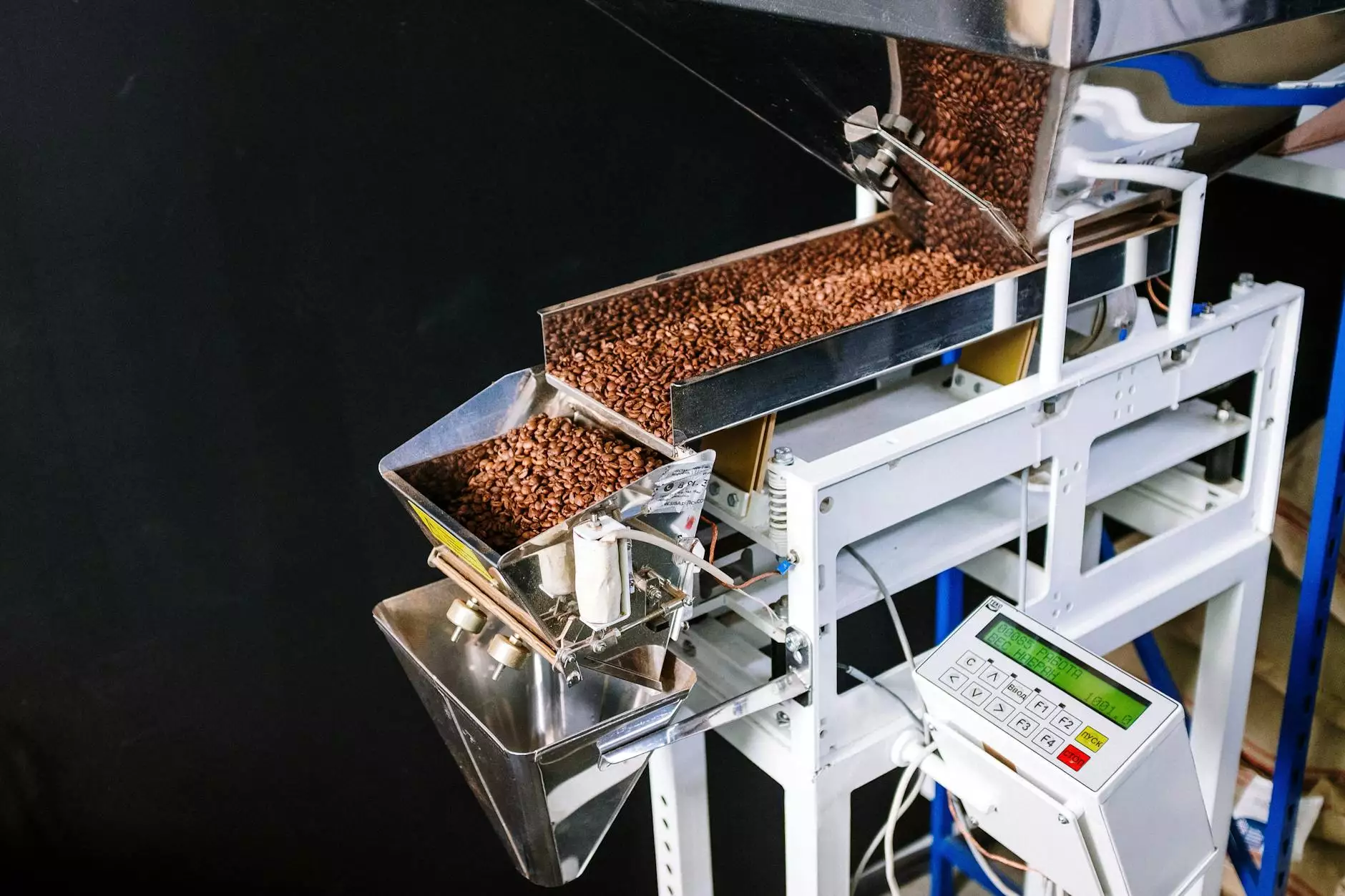

Understanding Concrete Mixing Plants

Concrete mixing plants are facilities where various raw materials, such as cement, aggregates, water, and additives, are combined to create concrete. The average consumer might not realize the sophistication involved in this process:

- Batch Mixing Plants: These plants produce concrete in batches, allowing for high customization and flexibility.

- Continuous Mixing Plants: Ideal for projects requiring consistent concrete production, these plants ensure a steady supply.

- Mobile Mixing Plants: These are perfect for remote locations, offering flexibility without sacrificing quality.

Innovations in Concrete Mixing Technology

Staying competitive in the construction industry requires adaptation and innovation. PolygonMach, a leader among concrete mixing plant manufacturers, embraces cutting-edge technologies that enhance both efficiency and quality in concrete production. Some of these innovations include:

1. Advanced Control Systems

Modern concrete mixing plants are equipped with automated control systems that allow for precision in the mixing process. These systems ensure that every batch meets the specified standards and reduces the risk of human error.

2. Eco-Friendly Solutions

With growing concerns over environmental impact, many manufacturers are now focusing on sustainability. This includes the development of recyclable materials, energy-efficient machinery, and systems designed to minimize waste.

3. Enhanced Mixing Techniques

Utilizing innovative mixing techniques, such as twin-shaft mixers, allows for a more homogenous blend of materials and significantly improves the overall quality of concrete.

Sustainability in Concrete Production

As environmental regulations tighten and society demands greater responsibility, sustainability has become a cornerstone for concrete mixing plant manufacturers. Here are several ways in which companies, like PolygonMach, are addressing these challenges:

- Use of Recycled Materials: Incorporating recycled aggregates into concrete production minimizes the demand for virgin resources.

- Energy Reduction Initiatives: Implementing energy-efficient practices within their operations reduces the carbon footprint and promotes sustainability.

- Water Management Systems: Advanced technologies to capture and reuse water ensure that plants operate efficiently while conserving this vital resource.

Challenges Faced by Concrete Mixing Plant Manufacturers

Although the industry is experiencing growth and innovation, several challenges persist. Key challenges include:

1. Market Competition

The construction market is saturated with numerous players, which can drive down prices and force manufacturers to innovate continuously to stay ahead.

2. Regulatory Compliance

Manufacturers must keep up with changing legislation regarding environmental standards and worker safety, which can require substantial investment to comply.

3. Supply Chain Disruptions

Global events can impact the supply of raw materials, making it vital for manufacturers to build resilient supply chains that can adapt to changing circumstances.

Future Trends in Concrete Mixing

As the demand for concrete continues, so does the need for innovation in the industry. Future trends include:

1. Digital Transformation

The use of IoT technology and data analytics will enhance operational efficiency and allow for real-time monitoring of concrete quality.

2. Automation and Robotics

Incorporating robotics into the production process will increase efficiency and reduce labor costs, allowing manufacturers to stay competitive.

3. Sustainable Construction Practices

As the construction industry moves towards sustainability, concrete mixing plant manufacturers will play a crucial role in developing greener solutions.

Choosing the Right Concrete Mixing Plant Manufacturer

Selecting the best manufacturer is critical for ensuring project success. Here are some factors to consider:

- Reputation: Research the manufacturer's reputation by checking reviews and case studies.

- Experience: A company with a proven track record in the industry will likely have the expertise needed to meet your project’s requirements.

- Technology: Evaluate the technology and machinery used by the manufacturer. Advanced machines can significantly optimize production.

- Customer Support: Ensure the manufacturer provides comprehensive support and maintenance for their products.

Conclusion

The role of a concrete mixing plant manufacturer is crucial in shaping the future of the construction industry. By embracing technological advancements and sustainable practices, manufacturers not only enhance their competitive edge but also contribute to the development of safer, more environmentally friendly infrastructure. As seen with PolygonMach, the commitment to innovation and quality will define successful players in this evolving industry.

In summation, as the demand for concrete grows, so too does the need for high-quality mixing plants backed by manufacturers who understand the intricacies of this vital material. Making informed choices will propel both contractors and manufacturers toward a more efficient and sustainable future in construction.